Contact us

Email: sales@hbyyfrp.com

Phone: +86 15131877882

WhatsApp: +86 15131877882

Fiberglass Industrial Park, Zaoqiang County, Hebei Province

Pultruded grid series

- 产品描述

-

Product Overview

FRP pultruded grating is a plate with gaps made by using FRP pultruded "l" shaped profiles as load-bearing bars, pipes and rods as connecting rods, and through certain assembly processes.

Product application fields

FRP pultruded grating is applied in fields such as water treatment, water supply and drainage, chemical and petroleum, power, papermaking, engineering construction, textile, printing and dyeing, and shipping.

Specific applications: operation platforms, stairways and walkways, stair railings, floors, manhole covers, walkways, pedestrian Bridges, equipment safety railings, scaffolding.

Product features

Pultruded FRP grating possesses most of the characteristics of molded FRP grating, but it also has significant differences. The most important one is the high glass fiber content (65%-70%) in the load-bearing bar direction. Therefore, compared with molded FRP grating, it shows more advantages when used in large spans, which will reduce the foundation support and lower the engineering cost.

Light weight: Pultruded grating weighs only about a quarter as much as steel, making it very easy to handle and thus reducing handling costs.

High strength: Pultruded grids offer a very high strength-to-weight ratio, with approximately 35% resin and 65% glass fiber by weight.

Uv resistance: Pultruded grating is formulated with UV absorbers and polyester surface felt to achieve the best UV resistance effect.

Flame retardancy: It has a flame retardant effect of grade 1 25 or an oxygen index of 26 or above. (As required by the project)

Chemical resistance: The selection of high-quality orthophthalic, isophthalic, vinyl ester resins and pultruded FRP grating with surface felt has excellent properties

Corrosion resistance.Other outstanding properties: impact resistance, maintenance-free, easy to process, anti-slip safety, insulation and heat preservation, etc.

Product dimensions and parameters

Grille specification Grille height (mm) Void ratio(%) Profile (vertical placement) specifications Grille Resin type Single weight kg/m2 high wide Thick tendons I-beam count per foot Center distance PI-10-40 25.4 40% 25.4 15.2 4 12 25.4 V,I,O 17 PI-10-50 25.4 50% 25.4 15.2 4 10 30.5 V,I,O 14.6 PI-10-60 25.4 60% 25.4 15.2 4 8 30.1 V,I,O 11.4 PI-15-40 30.1 40% 30.1 15.2 4 12 25.4 V,I,O 22.5 PI-10-50 30.1 50% 30.1 15.2 4 10 30.5 V,I,O 10.5 PI-10-60 30.1 60% 30.1 15.2 4 8 30.1 V,I,O 10.0 Safety load-bearing performance table

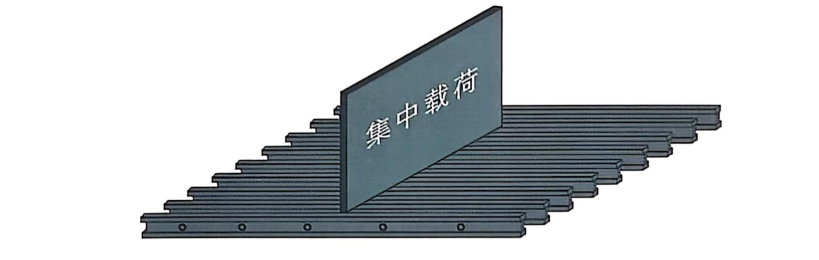

Span Model Concentrated load (inches @ pounds per square foot) Maximum load capacity 100 200 300 400 500 750 1000 1800 2000 3000 4000 18 PI-10-60 0.06 0.08 0.10 0.15 0.18 0.29 0.38 7640 PI-15-60 0.01 0.02 0.02 0.03 0.04 0.06 0.08 0.12 0.15 12050 24 PI-10-60 0.10 0.12 0.17 0.22 0.33 0.44 0.65 0.87 5811 PI-15-60 0.02 0.03 0.04 0.04 0.06 0.09 0.13 0.17 0.25 0.33 9000 30 PI-10-60 0.13 0.16 0.20 0.29 0.39 0.58 0.78 1.17 1.56 4710 PI-15-60 0.02 0.03 0.06 0.06 0.08 0.11 0.15 0.22 0.3 0.44 0.59 7060 38 PI-10-60 0.13 0.19 0.25 0.31 0.46 0.62 0.93 1.24 1.88 2.48 3080 PI-15-60 0.02 0.05 0.08 0.09 0.13 0.18 0.24 0.37 0.49 0.74 0.99 5700 42 PI-10-60 0.11 0.21 0.32 0.42 0.52 0.77 1.03 1.57 2.09 3.13 4.17 3300 PI-15-60 0.04 0.08 0.12 0.16 0.19 0.29 0.38 0.57 0.76 1.14 1.52 4800 49 PI-10-60 0.16 0.31 0.46 0.61 0.76 1.15 1.53 2.28 3.02 4.57 6.08 2000 PI-15-60 0.06 0.11 0.17 0.22 0.28 0.42 0.57 0.84 1.12 1.88 2.24 4070 54 PI-10-60 0.22 0.44 0.65 0.87 1.09 1.64 2.18 3.27 4.36 6.55 2500 PI-15-60 0.08 0.18 0.29 0.32 0.4 0.57 0.79 1.15 1.52 2.29 3.12 3480

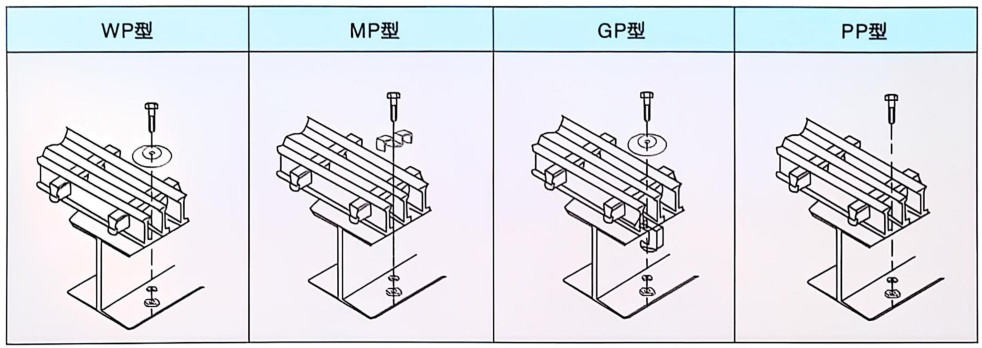

Span Type number Concentrated load (inches @ pounds per square foot) Maximum load capacity 40 60 100 200 400 600 800 1000 1500 2000 3000 4000 18 PI-10-60 0.01 0.02 0.03 0.04 0.06 0.07 0.11 0.15 0.22 0.29 9800 PI-15-60 0.01 0.01 0.02 0.03 0.03 0.05 0.07 0.1 0.14 15650 24 PI-10-60 0.03 0.05 0.09 0.13 0.18 0.22 0.33 0.44 0.66 5900 PI-15-60 0.01 0.01 0.02 0.04 0.05 0.07 0.09 0.13 0.18 0.26 0.35 8900 30 PI-10-60 0.06 0.12 0.20 0.28 0.37 0.47 3810 PI-15-60 0.01 0.02 0.04 0.08 0.12 0.15 0.19 0.29 0.38 0.58 5650 36 PI-10-60 0.07 0.12 0.23 0.43 0.64 2700 PI-15-60 0.02 0.03 0.05 0.09 0.16 0.23 0.31 0.39 0.58 3850 42 PI-10-60 0.09 0.14 0.22 0.42 1820 PI-15-60 0.04 0.05 0.08 0.16 0.03 0.45 0.06 2720 48 PI-10-60 0.15 0.22 0.36 0.7 1420 PI-15-60 0.06 0.09 0.14 0.26 0.51 2032 54 PI-10-60 0.25 0.37 0.59 1250 PI-15-60 0.1 0.14 0.23 0.44 1532 Install accessories

Keywords: