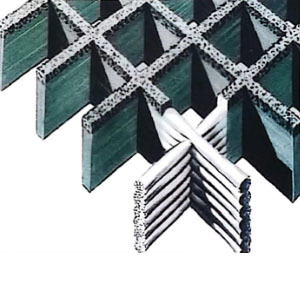

FRP molded grating is made by cross-weaving glass fibers and pouring resin for integral molding.

◆ The interlaced weaving of glass fibers and the full impregnation of resin make the grating highly resistant to corrosion.

◆ The glass fiber and resin are formed by cross-crossing composite molding. The overall structure evenly distributes the load, which is conducive to the uniform force distribution of the grid installation and its installation support structure, and enhances the load-bearing capacity.

◆ Wear-resistant and anti-slip surface layer: The concave surface of the grating gives it anti-slip performance, and the anti-slip effect is even better on the sand-covered surface.

◆ The glossy surface of the grating and the inclined grating surface give the grating a self-cleaning effect.

Contact us

Email: sales@hbyyfrp.com

Phone: +86 15131877882

WhatsApp: +86 15131877882

Fiberglass Industrial Park, Zaoqiang County, Hebei Province

Molded grating series

- 产品描述

-

Product Overview

Molded FRP grating is A type of grating with unsaturated polyester resin (including isophthalic type, orthophthalic type, vinyl type, phenolic type, bisphenol A type, etc.) as the matrix and glass fiber roving as the skeleton. It is formed by weaving and pressing on metal molds or hand lay-up and then heated as a whole. The product has a smooth and beautiful appearance, high internal quality, and a glass fiber content of over 30% (by weight percentage).

Product application fields

FRP molded grating is applied in fields such as chemical engineering, petroleum, metallurgy, power, electroplating, storage batteries, machinery, pharmaceuticals, printing and dyeing, mining, sewage treatment, house decoration, municipal engineering, car washes, etc.

Specific applications: operation platforms, manhole covers, double-layer floors, walkways, passageways, stair treads, ceilings, tree protection boards, car wash room floors, etc.

Product Features

(1)It is resistant to corrosion by various chemical media, never rusts, has a long service life and requires no maintenance.

(2) Flame retardant.

(3) Insulating and non-magnetic.

(4) It has a slight elasticity, which can reduce personnel fatigue, enhance comfort and improve work efficiency.

(5) It is lightweight, high-strength, and easy to cut and install.

(6) Uniform colors both inside and out can be chosen at will. We can customize colors according to customers' requirements and improve the environment of the production site.

(7) It has relatively good comprehensive economic benefits.

(8) It has strong designability and flexible and diverse sizes.

Manufacturing process

Product type

FRP molded grating can be classified into common type, original color transparent type, groove type, sand-laid type (anti-slip type), double-layer small hole type, surface ground type, cover plate type and cover plate sand-laid type according to its application and appearance.

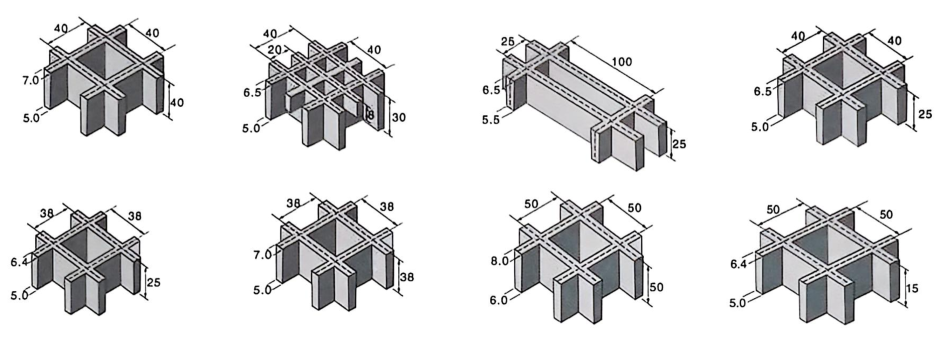

Product dimensions and parameters

Grid thickness(mm)

Single cell size(mm×mm)

Length × width(m/m)

The upper rib is wide(mm)

Lower rib width(mm)

Hole entry rate%

Weight of the display board(kg)

40

40×40

1007×3007

7

5

64

60

30

20×20

1007×4047

6.5

5

40

00

25

100×25

1007×3007

6.5

5.5

60

35

25

40×40

1007×3007

6.6

5

64

33

25

30×30

1220×3060

6.4

5

60

52

30

30×30

1220×3060

7

5

60

00

50

50×50

1220×3060

0

0

72

100

15

50×50

1220×3060

6.4

5

72

20

Data table of centralized load and evenly distributed load on the entire board

1007×3007×40(mm), with a grid of 40×40(mm)

Support distance(mm)

The central load KGS width is 90cm

Deformation(mm)

Uniformly distributed load KG/SQM

Deformation(mm)

1000

558

6

860

6

900

690

6

1172

6

600

2137

8

5830

8

1007×3007×25(mm), with a grid of 40×40(mm)

Support distance(mm)

The load at the center of the entire plate under 1% deformation (KGS)

Uniform load under 1% deformation load (KGS/SQM)

250

-

-

500

830

5200

750

460

1270

1000

305

492

1007×3007×25(mm), with a grid of 25×100(mm)

Support distance(mm)

The load at the center of the entire plate under 1% deformation (KGS)

Uniform load under 1% deformation load (KGS/SQM)

250

1300

-

500

380

3130

750

207

835

1000

160

335

1220×3660×38(mm), with a grid of 38×38(mm)

Support distance(mm)

The load at the center of the entire plate under 1% deformation (KGS)

Uniform load under 1% deformation load (KGS/SQM)

457

-

8503

610

900

3592

762

660

1710

914

570

1075

1067

418

685

1219

318

464

1220×3660×50(mm), with a grid of 50×50(mm)

Support distance(mm)

The load at the center of the entire plate under 1% deformation (KGS)

Uniform load under 1% deformation load (KGS/SQM)

610

1558

6328

762

1000

3226

914

704

1881

1067

581

1173

1219

504

782

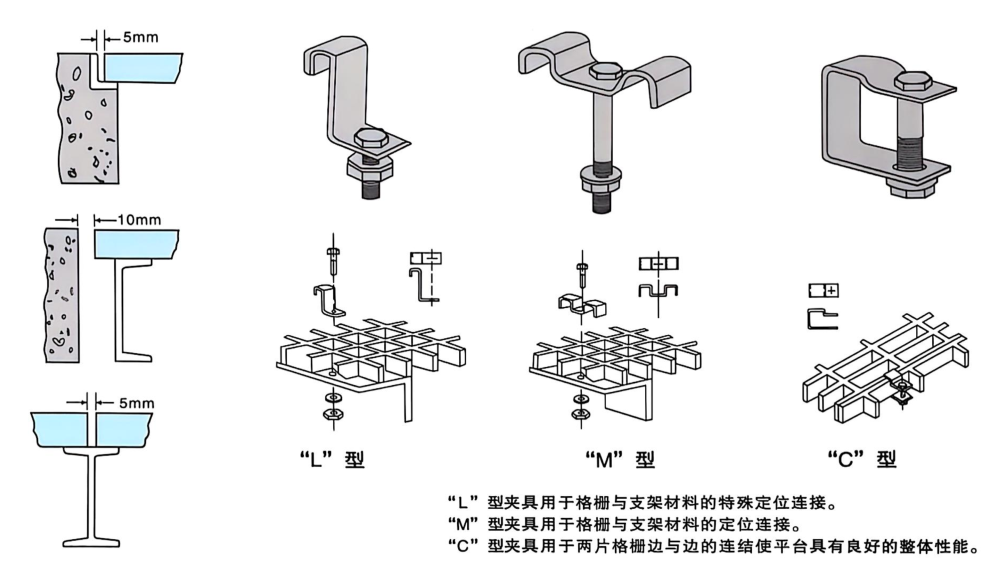

Installation and accessories

Keywords: